| If you do

NOT see the Table of Contents frame to the left of this page, then

Click here to open 'USArmyGermany' frameset |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

General Support Center, Kaiserslautern |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| GSCK History | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1951 - 1989 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (Source: Welcome to General Support Center, Kaiserslautern. Compiled by GSCK in 1989) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| KMC History | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (Source: Welcome to General Support Center, Kaiserslautern. Compiled by GSCK in 1989) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Construction

of the Kaiserslautern Maintenance Center (KMC) began in 1951 as

a post-WWII effort to provide heavy engineer/rail equipment repair

for the European Theater.

By 1953 it became fully operational as the Rhine Engineer Depot, a government-owned, contractor operated facility. Since 1956, it has been government operated, supporting the 200th Theater Army Materiel Management Center (200th TAMMC) End Item Maintenance Program for tactical wheel and combat vehicles, construction equipment and generators. Throughout its history, KMC has repaired such diverse equipment as rail locomotives, army boats, and most recently, the M1 Abrams Main Battle Tank. In 1983, it became a USAREUR Special Repair Activity/General Support Maintenance Center and was renamed as the Kaiserslautern Maintenance Center (KMC). It is the largest general support maintenance center outside of the Continental US. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8121st CSG History | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (Source: Welcome to General Support Center, Kaiserslautern. Compiled by GSCK in 1989) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The

unit was organized as the 8121st Labor Service Engineer Depot Company

(German) on 24 August 1950 at the Hanau Engineer Depot.

Upon reorganization of the Army Storage Supply System (in Europe) in 1952, the unit and depot stocks were transferred on 3 September 1953 to the newly constructed Rhine Engineer Depot, Kaiserslautern. The Rhine Engineer Depot later became the Kaiserslautern Army Depot and is now known as General Support Center, Kaiserslautern |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8593rd CSG History | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (Source: Welcome to General Support Center, Kaiserslautern. Compiled by GSCK in 1989) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The

8593rd Civilian Support Group was activated on 24 August 1950, as

the 8593rd Labor Service Platoon (Engineer Bridge Maintenance).

The Platoon was assigned to the Rhine Engineer Depot in Kaiserslautern.

All members of the Platoon were Lithuanian when the unit was activated.

The assigned mission was to maintain tactical load bridges (Class 60 and Bailey Bridges) in operational condition. In December 1983, the unit was redesignated as the 8593rd Civilian Support Group (Maintenance, Direct Support). A Group was formed in Kaiserslautern to perform maintenance as well as smaller repairs on vehicles stored within the Reserve Storage Activity, Kaiserslautern. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8907th CSG History | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1986 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(Source: SUPPORT SENTINEL, Feb. 25, 1986 (Vol. 12, No. 4) |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

More than 3,800 "junker" jeeps entered the 8907th Civilian Support Gp assembly line and rolled off almost as good as new at the General Support Center Kaiserslautern during the last 4 1/2 years. The reconditioning program -- officially called the USAREUR Quarter-Ton Truck Sustainability Program -- ended in mid-February when the last of the familiar vehicles received its new body kit. "The Army isn't buying any more replacement body kits for its quarter-ton truck fleet," said Johannes Jahn, the 8907th's supervisor. "The USAREUR fleet is much smaller today than it was five years ago because of units are phasing in CUTVs (commercial utility tactical vehicles) and HMMWVs (high mobility multipurpose wheeled vehicles)." When USAREUR designated his unit as the central repair point for its 10,000 jeeps in October 1981, an average of 50 of the vehicles became unserviceable every month because of rusted out bodies and worn-out parts, Jahn said. The 8907th mechanics faced the challenge of getting 600 jeeps back on the road during fiscal year 1982. "We met our production quota on time and attached a comment card to the log book of each truck to get feedback from the users," Jahn said. "We never received any complaints." Output increased to 840 quarter-ton trucks in FY '83 and 960 in FY '84. "During May 1984 we hired 35 additional mechanics to boost production to 1,150 jeeps for FY '85," he said. "As of Dec. 31, 1985, a total of 3,820 quarter-ton trucks were completely reconditioned. With the jeep currently valued at $19,000, the reconditioning program saved the Army about $40 million. "Our inspection section checks each truck for serviceability and determines whether the repair costs will exceed the maintenance expenditure limitation," Jahn said. If the vehicle can be repaired for less than $5,000, inspectors prepare a job order and the jeep comes to the 8907th for repairs. "At the start of fiscal 1986, we had only 350 replacement body kits remaining for the Quarter-Ton Sustainability Program," he said. "However, we are still scheduled to repair 950 jeeps per year through 1989. The remaining 600 trucks will be processed under the IROAN program -- inspect, repair only as needed. Instead of installing a complete new body kit, we'll inspect each vehicle, note deficiencies and repair only those parts that are defective." Under the Swap-Out Program, only 580 jeeps turned in for repair during FY '86 will be returned to the sending units, Jahn said. The rest will go to reserve storage activities to become part of war reserve stock. Quarter-ton trucks that would cost more than 25 percent of their market value to repair will be scrapped. "The personnel assigned to the 8907th made the Quarter-Ton Truck Sustainability Program a success," Jahn said. "Our mechanics, administrators, supply and transportation people are professionals trained to work on all kinds of wheeled vehicles. "If we had to stop working on jeeps, we would switch over to other vehicles," he said. "Maybe within the next three years, the Army will have us repairing half-ton trucks or CUTVs, but we'll be ready." |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1989

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (Source: Welcome to General Support Center, Kaiserslautern. Compiled by GSCK in 1989) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The

8907th Civilian Support Group was activated on 1 April 1976 as the

8907th Civilian Labor Group (Heavy Equipment Maintenance). The unit

was organized under LS-TDA LS-EI-WB0Q04-00 and first assigned to

Headquarters and Headquarters Detachment, 66th Maintenance Battalion

(DS/GS), Kaiserslautern.

Effective 1 October 1978, the unit was reassigned to the 29th Area Support Group, Kaiserslautern. Effective 16 August 1980, the 8907th CLG was assigned to the US Army Maintenance Activity, Germersheim. Effective, 16 January 1982, the unit was redesignated as the 8907th Civilian Support Group (Maint, GS/DS). Effective 29 June 1982, the 8907th CSG was assigned to the General Support Center, Kaiserslautern. On 1 October 1981, the 8907th CSG was designated as the Centralized Repair Facility for the USAREUR Jeep Sustainability Program. 3,900 ¼-ton trucks, M151A2 (Note: Military Utility Tactical Truck, or `MUTT'), were scheduled to be upgraded under this program. The program was completed on 31 March 1986. Starting on 1 April 1986, the program was changed from a line operation (body replacement) to a repair program under the IROAN (Inspect, Repair Only As Needed) Concept. A total of 910 ¼-ton trucks were completed under that program. Effective 1 May 1987, the repair procedures returned to a line operation with complete disassembly of the truck, sandblasting and repair of body. In September 1987, the 8907th CSG completed the 5000th ¼-ton truck. Most of the ¼-tons are in use by Active Army units in the Theater. The ¼-ton program ended on 1 March 1989 when the last ¼-ton was produced bringing the total to 5250. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8910th CSG History | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (Source: Welcome to General Support Center, Kaiserslautern. Compiled by GSCK in 1989) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

With

the implementation of the Modernization of Logistics Program (MODLOG)

in USAREUR, the 8910th Civilian Support Group was organized, effective

1 October 1976, to establish a general support supply base (GSSB)

for the 21st Support Command and assigned to the 9th Materiel Management

Center (9th MMC).

The GSSB title was changed to Pre-Positioned War Reserve Materiel effective 13 January 1988. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

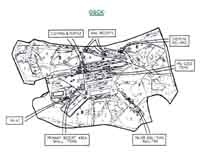

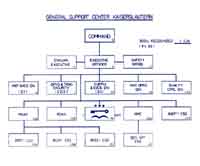

| GSCK Organization and Missions | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (Source: Welcome to General Support Center, Kaiserslautern. Compiled by GSCK in 1989) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

GENERAL

INFORMATION

Personnel |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Funding

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Miscellaneous

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

ORGANIZATION

SAFETY OFFICE MISSION: Plans, establishes and monitors a sound and successful safety program. Provides technical advice to Commander, General Support Center, Kaiserslautern and staff in accident prevention and compliance with occupational safety and health act. QUALITY CONTROL DIVISION MISSION: Provides quality control systems and technical inspection support to assure that all TR-1 supply materiel received, stored, maintained, repaired and issued by the Center meets prescribed quality standards. Interprets and implements quality control and reliability concepts and techniques. Establishes liaison on quality control matters with higher headquarters, inventory control points and civilian contractors with regard to quality standards and specifications. Provides calibration and test laboratory support. Provides for continuing analysis and evaluation of quality systems and data. Certifies special skills and processes which are required for Theater supply and maintenance functions. Maintains technical reference library of publications applicable to materiel stored by this Center. MANAGEMENT SERVICES DIVISION MISSION: Serves as principle advisor on management issues to include budget, manpower management, personnel management and administration. Serves as point of contact for all external reviews, surveys, inspections and audits conducted by AAA, GAO, USAREUR, 21st TAACOM and 29th ASG. Conducts self-assessment and prepares command replies. Manages and monitors the Model Installation Program (MIP). Coordinates the GSCK training program. MATERIEL OPERATIONS DIVISION MISSION: Serves as principle staff advisor to the Commander, GSCK on matters pertaining to assigned supply, maintenance and logistics services, plans, policies and programs. Serves as the central point for the development and publication of operating procedures and policies. Provides guidance on technical and procedural matters. Conducts training on the introduction of new concept systems, policies and procedures. Advises and assists on matters relating to the General Support Repair Program (GSRP) mission of the command. Monitors the Care Of Supplies In Storage (COSIS) Program for Theater Command Stocks. SUPPLY AND SERVICES DIVISION MISSION: Supports all of GSCK activities with organization and mission supplies and 29th ASG with installed equipment maintenance. Monitors, edits and prepares all requisitions for addition/deletion of equipment to the table distribution allowances (TDA) in accordance with AR 310-34. Operates automated data processing system for DS4 and independent reserve storage activity system. Serves as deputy installation coordinator for the 29th ASG, coordinates installation projects with appropriate directorates and contractors. Operates Box and Crates Section. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

RESERVE

STORAGE ACTIVITY, KAISERSLAUTERN

MISSION: Receives, stores and issues peacetime operating stocks as a storage site for the 200th TAMMC; receives, stores and maintains Theater Reserve, Decrement, and Operational Project stocks as directed by the 200th TAMMC; operates the Break Bulk Point for Kaiserslautern area customers; operates the Retrograde Processing Point; and operates the 21st TAACOM's Pre-Positioned War Reserve Materiel for the 9th Mat Mgt Ctr. STORAGE DIVISION MISSION: Manages receipt, storage, shipping, set assembly, safeguarding, and space utilization of Pre-Positioned War Reserve Materiel stock, major items, secondary items, basic issue items and weapons. Operates the USAREUR Retrograde Processing Point (RPP), processes all field returns, and maintains supplies and equipment in storage. TRANSPORTATION DIVISION MISSION: Functions as traffic manager for the 29th ASG. Performs the customs clearance authority function for the installation transportation officer (ITO). Operates the Break Bulk Point (BBP), Kaiserslautern, serving approximately 118 customers within Rheinland-Pflaz, and the Distribution Drop Point (DDP) for the Kaiserslautern area. MATERIEL MANAGEMENT DIVISION MISSION: Manages and controls all supply transactions processed for materiel stored at Reserve Storage Activity, Kaiserslautern. Theater Army materiel management items. Manages inventory and location surveys for all classes of supplies less food, bulk petroleum, ammo and medical. CARE AND PRESERVATION DIVISION MISSION: Directs, supervises, and controls the Care Of Supplies In Storage (COSIS) program. Ensures the true condition of materiel is identified and recorded. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

8121st

CSG

MISSION: Supports the Reserve Storage Activity and 29th ASG by providing management, adminstrative and technical personnel, for receipt, storage, in-storage maintenance, issues of supplies and equipment, packing and preservation and transportation services. Operates a consolidated dining facility. Maintenance support to the Breitenwald Training Area (rifle range). Administrative, logistical and service support to Headquarters Company, 29th ASG, operation in support of the Directorate of Logistics (DLOG) and the Directorate of Materiel (DMAT). 8593rd CSG MISSION: Receives, stores, maintains and issues Pre-Positioned War Reserve Material Stock (PWRMS) for the RSAK. Performs limited general support, direct support and operational maintenance for automotive vehicles and equipment at Kaiserslautern and North Point. Provides the V Corps Forward Storage Sites, located at Flensungen, Grebenheim, Alsberg and Grossauheim, with maintenance. Performs care of supply in storage, exercising, processing and serviceability tests on vehicles and trailers. Supervises and performs organizational and direct support, limited general support maintenance on vehicles and trailers organic to the 8910th CSG and the 5th QM Detachment (AD). 8907th CSG MISSION: Provides DS/GS maintenance as directed. The FY 1989 program will include CUCV and HUMVEE vehicles. 8910th CSG MISSION: Receives, stores and issues war reserve materiel for the 21st TAACOM. Performs receiving, storage and issue of general supplies except those associated with subsistence, petroleum, medical, ammunition, cryptographic functions, airdrop peculiar supplies, and marine and rail supplies. Maintains the 21st TAACOM Theater Operation Readiness Stock. Participates in the execution of the intra-theater air delivery system (SHERPA), used to provide collecting, processing, and delivery of high priority parts and equipment throughout Europe. Supports the Aircraft Processing Detachment, 70th Trans Bn, at Ramstein Air Base for Closed Loop Support, Aircraft, USAREUR (CLS). Provides direct support for a variety of US and NATO exercises. Furnishes personnel to support the CSG Consolidated Dining Facility at Verdun Kaserne and/or to feed unit personnel when operating away from the garrison. KAISERSLAUTERN MAINTENANCE CENTER MISSION: Provides DS/GS repair to support: --- the USAREUR General Support Repair Program (GSRP) for 30 line items in support of the theater logistics system; --- the 21st TAACOM General Support Program in support of user units. --- Care Of Supplies In Storage (COSIS) minor repair as needed for theater reserve stocks. GENERAL SUPPORT SUPPLY SUPPORT ACTIVITY MISSION: WK4FV9, Class IX (Repair Parts) Account, is the second largest supply activity in 21st SUPCOM. Provides repair parts to the Kaiserslautern Maintenance Center in support of the M1A1 Abrams Tank Program. Provides repair parts to the 8907th CSG in support of their repair programs. Provides repair parts to all customers in support of the General Supply Repair Program (GSRP) and Care Of Supply In Storage (COSIS). With the coordination between 9th Support Center and 200th TAMMC, provides M1 parts to support the retrograde program to Reserve Storage Activity, Eygelshoven, the 54th ASG and the Reserve Storage Activity, Luxembourg, RESERVE STORAGE ACTIVITY, NAHBOLLENBACH See the Nahbollenbach Army Depot Page 5th QUARTERMASTER DET (AIR DELIVERY) See the 5th QM Det (AD) Page (will be added soon) |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Related

Links

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||