| If you do

NOT see the Table of Contents frame to the left of this page, then

Click here to open 'USArmyGermany' frameset |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Ordnance

Division |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| The 1970s | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Maintenance Doctrine | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (Source: ARMY LOGISTICIAN, March-April 1980) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| The article by Martin Reuss, who served as a Senior Historian for the US Army Corps of Engineers from 1978 to 2006, provides an interesting overview of the evolution of US Army maintenance doctrine. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| GS/DS Maintenance in USAREUR | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1975/76 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (Source: USAREUR Annual Report CY 1975) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| USAREUR Support Maintenance Capability Study | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| In 1974 USAREUR undertook a review of its maintenance organization and policy.

The study was necessitated by a number of factors that were impacting the command's maintenance capabilities: reductions in theater depot maintenance in USAREUR; the new logistics echelons above division (EAD) doctrine; the impact of Project CHASE reorganizations; and the reductions in non-combat strengths required by the Nunn Amendment. In 1974 USAREUR's combat service support maintenance resources were organized into six direct support (DS) and four general support (GS) battalions:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| The DS battalions were organized with one "rear" and two "forward" DS companies and an attached supply and services company. The battalions provided direct support maintenance on an area basis. Two DS battalions were assigned to each corps and two to the 1st Support Brigade. Backing up the DS battalions and stationed relatively further in the rear, were corps-level GS battalions: two in VII Corps, one in V Corps and one in the 1st Support Brigade. These were organized with one light equipment maintenance (LEM); two heavy equipment maintenance (HEM) companies and a collection and classification company. One of the concepts proposed by the capability study called for a balanced program that would distribute the command's maintenance workloads among the two corps, the 1st Support Brigade and theater-level maintenance facilities. This reorganization concept plan was selected and formally approved in November 1974. The effective dates for the resulting reorganizations were phased across an 8-month period, beginning in November 1975 and scheduled for completion in June 1976. By the end of the implementation effort the USAREUR DS/GS maintenance organization would be as shown in the chart below: |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| The concept approved in late 1974 called for unique area support battalions to be organized under USAREUR-developed MTOE tailored to the specific requirements of the area that each would support. Although they would not be identical, the battalions would be composed of the same basic elements:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Except for aircraft, ammunition, missiles, medical, and communications security and cryptographic equipment, all combat service support maintenance would be provided by these area battalion, including both direct support to non-divisional units and general support to both divisional and non-divisional units. The programming and management of repair activities within their respective commands would be controlled by the materiel managment centers of the two corps and 1st Support Brigade. Maintenance requirements that exceeded the capabilities of the area support battalions -- together with types of maintenance specified for performance at designated theater-level repair facilities -- would be programmed and managed by the USAMMAE materiel management center, which would subsequently be reassigned as a USAREUR element. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Class V Ordnance Service in USAREUR | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1977 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (Source: Annual Historical Review, HQ 21st SUPCOM, 1 Jan - 31 Dec 1977) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| In a move to decentralize conventional ammunition management, the 60th Ordnance Group underwent a major reorganization in 1977. In April 1977, the 15th Ordnance Battalion of the 60th was transferred to V Corps and in October the Group's 101st Ordnance Battalion was transferred to VII Corps. In spite of these changes, the commander, 60th Ordnance Group, remained as the overall theater commodity manager for control of ammunition stocks for these battalions. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1978 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (Source: Annual Historical Review, HQ 21st SUPCOM, 1 Jan - 31 Dec 1978) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| The 60th Ordnance Group expanded its 84th Ordnance Battalion ammunition supply operations into the NORTHAG area with the activation of the 48th Ammunition Detachment at Bremerhaven in May 1978 in support of Brigade 75 (this unit, relocated to Garlstedt, would soon be redesignated as 3rd Bde, 2nd Armd Div). Prior to becoming fully staffed, this detachment was active in support of REFORGER 78 and received abnd stored ammunition at Luebberstedt, Walsrode and Olfen in the NORTHAG area. Also, 44th Ordnance Company was activated at Baumholder on 21 Mach 1978 to operate Ammunition Supply Point #4 in direct support of 8th Infantry Division. Ammunition Call Forward Plan All divisions of 60th Ordnance Group were actively involved in the FY 1979 Ammunition Call Forward Plan. This plan, which proposed shipment of over 240,000 short tons of munitions from CONUS to USAREUR, underwent an intensive study to determine the ability of USAREUR to receive, move, and store the proposed tonnage. In coordination with the Corps (V and VII), 4th Transportation Brigade, Military Traffic Management Command (MTMC), Transportation Terminal Group, Europe, Miesau Army Depot, Caerwent Army Depot Activity and the 84th Ordnance Battalion, data was developed which resulted in a recommendation that tonnage proposed in the plan be reduced to 170,000 short tons. POMCUS NORTHAG Three former British Army of the Rhine (BAOR) sites were transferred to USAREUR control for construction of storage and maintenance facilities for the NORTHAG POMCUS equipment: Herongen Ammunition Depot, Twisteden Ammunition Depot, and South Park (Ayrshire Barracks, Mönchengladbach-Rheindahlen). Webmaster Note: the conventional ammunition stocks held at Twisteden were probably the basic load for 2nd Armored Division combat units that would arrive from CONUS and that would receive their equipment from the POMCUS sites in the event of hostilities. The PSP at Lübberstedt, on the other hand, could have been the basic load for the 3rd Brigade already forward stationed in NORTHAG area. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Ordnance - Special Weapons Support | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (Source: USAREUR STATION LIST, 1 June 1976, and other public sources) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Nuclear Surety Inspections | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (Source: Email from Andrew J. Johnson, USAREUR IG Section, 1977-79) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| My next brush with the 59th Ordnance Brigade and its predecessors was June 1977 – June 1979. I was assigned to the IG shop at USAREUR Headquarters in Heidelberg, Germany and conducted Nuclear Surety Inspections throughout Germany, Belgium, Italy, Greece, and Turkey. In 1978, I conducted the first ever NSI of the chemical storage site of the 636th Ordnance Company (part of the 60th Ordnance Group) near Munchweiler. A copy of the LOC was sent to the Commander of the 82nd Ordnance Battalion. (Click here to read Col Johnson's recollections of his other assignments to 59th ORD units: 35th Arty Det; 525th Ord Co; BC of 197th Ord Bn) ADDITIONAL INFORMATION An inspection team was typically a LTC Team Chief, Major Deputy Chief, and 2-3 Warrant Officers. It depended a little on whether we were inspecting a NIKE, field artillery, or Pershing unit. When we went into Italy, Greece, and Turkey, we often took two teams so we could share the Warrant Officers if sites were in close proximity. These trips were usually two weeks long so we could cover at least four sites. Inspections of Ordnance companies took the longest because we had to put a crew through maintenance procedures on every type of weapon system they held. Our preparation usually included reading up on the unit, its mission, and its past performance. If they exhibited a weakness in the past, we wanted to see if corrective action had been taken. Although we had a poor reputation, we never wanted to fail a unit. We knew what that meant for the careers of those that were assigned to the unit. On occasion, we saw the impact of a failure on our NATO allies. I recall being in Greece once and discussing what to do because the brake lines on all the Honest John trailers were dry rotted. We decided to sleep on it and decide in the morning. When we arrived at the site the next morning we learned that the Greek commander had been hospitalized with a heart attack. Inspection outcomes often took very curious turns. I recall an inspection at a Pershing unit. Everything was going perfectly for the unit. We asked the unit to assume they had just had a lightning strike and to take all the appropriate actions. They took every action perfectly. Our Warrant congratulated the crew on its performance and then a young soldier said – but that’s not how we did it last week when lightning actually did strike the launch pad. A subsequent records review showed that they had in fact messed up several things, to include leaving a suspect warhead mounted to the missile. One of the things that always bothered us (the inspection teams) was that units would hold their top performers in place until the inspection was over and then release them. Often, when we got on the plane to go home, half of the crew we just inspected was leaving too. We often wondered what would happen if we got back off the plane and had another inspection. While the folks on the ground often felt great pressure, the inspectors had pressures too. I was gone from my wife and three young kids 75-80 % of the time. If we went out on a 2-week inspection, we typically got the next week at home to do paperwork. If we did weekly inspections, we might be gone Monday – Friday for several weeks in a row, have a week at home to get ready for a longer trip and then take off for 14 days. I did this for 2 years and then took command of the 197th for 2 years. Momma pretty much raised the kids single handedly. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| The 1980s | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Foreign Nationals providing Ordnance Maintenace in USAREUR | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1985 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (Source: The Role of Civilians in Maintaining Military Equipment, Vol. II, Joseph R. Wilk, Eugene A. Narragon & Brian E. Mansir, Logistics Management Institute, December 1985) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| The following section of the above report describes the nature and extent of direct maintenance support provided to the US Army in Europe by one of three civilian sources (Foreign nationals, Civilian Support Units, and Host Nation support) (1). Foreign Nationals The use of foreign nationals in Army maintenance is concentrated at Installation Materiel Maintenance Activities (IMMAs). The 59 IMMAs in Europe are located primarily in the Federal Republic of Germany (FRG) and are known under a variety of names, including motor maintenance activity (MMA), equipment support activity (ESA), consolidated maintenance center (CMC), logistic support activity (LSA), general equipment support activity (GESA), general equipment repair point (GERP), and theater maintenance center (TMC). They are staffed by foreign nationals and they employ from 3 to nearly 400 personnel. The IMMAs primarily provide direct support (DS) and general support (GS) maintenance for equipment in several commodity areas, including automotive, construction, combat vehicles, communications-electronics, audio-visual and training, general equipment, commodity groups, and weapons/armament. Although an IMMA may be assigned maintenance missions in a few, or even all, commodity areas, only those that have significant missions in five particular commodity areas are of interest. These five commodity areas are automotive, construction, combat vehicles, communications-electronics, and weapons/armament. The 18 IMMAs that support those commodities are called consolidated maintenance centers, equipment support activities, or theater maintenance centers. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

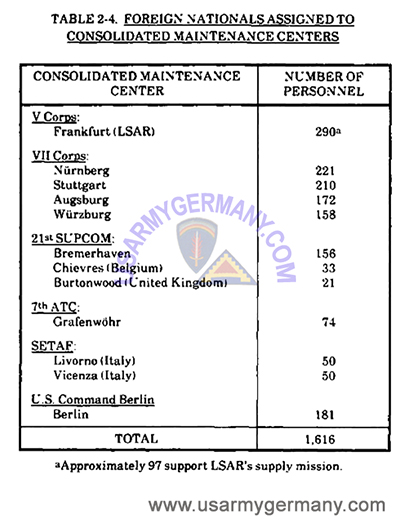

| Table 2-4 shows the locations and staffing of the Consolidated Maintenance Centers (CMCs). The Logistic Support Activity Roedelheim (LSAR), FRG (2), is included in this table because its role and organizational placement are similar to those of a CMC. The CMCs in the corps have been assigned DS/GS maintenance missions for automotive, construction, and communications-electronics equipment. None has been assigned weapons/armament missions except LSAR, which supports small arms; nor has any corps CMC been assigned a mission to support combat vehicles. The CMCs in the 21st Support Command (SUPCOM) also have DS/GS mission assignments for automotive, construction, and electronics-communication equipment, with CMC Bremerhaven assigned the additional mission of combat vehicles (except tanks). In the 7th Army Training Command (ATC), CMC Grafenwöhr has been assigned missions only for automotive and construction equipment, whereas both CMCs in the Southern European Task Force (SETAF) have mission assignments in all commodity areas except combat vehicles. CMC Berlin has a DS/GS mission for all commodities. Table 2-4 also shows that the Army employs 1,616 foreign nationals in its CMCs, with LSAR and the VII Corps CMCs comprising nearly two-thirds of that total. The LSAR is the only activity listed in the table with a large supply mission; approximately two-thirds of its personnel support the maintenance mission, while the balance supports supply. The CMCs are predominantly civilian organizations. Only LSAR and CMC Vicenza, Italy, with 15 and 30 military personnel, respectively, are assigned more than 5 military personnel. Furthermore, the CMCs employ very few DACs - a total of 13 for all 12 organizations. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

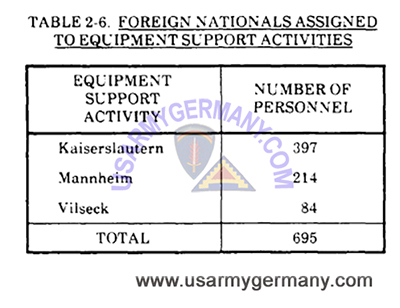

| Some of the CMCs deserve extra attention because they support the U.S Army Europe (USAREUR) Theater Army Repair Program (TARP). These CMCs and the extent of their contributions to the Fiscal Year (FY) 1985 TARP are shown in Table 2-5. The LSAR is the largest CMC contributor to the TARP. Its theater repair assignments include overhauling commercial automotive engines (35 to 40 different models), tactical engines (M880 and M151 series), and material handling equipment (MHE). The MHE overhauls include the 6,000 and 10,000 pound rough terrain forklifts. In addition to theater-wide GS assignments, LSAR also performs several V Corps GS functions and in its DS role, which is approximately 30 percent of its maintenance workload, it supports a wide variety of equipment. Another illustration of the nature of the work performed by CMCs is the mission of the CMC Nürnberg. That CMC supports the TARP by overhauling automatic transmissions from M880 trucks and nontactical vehicles, as well as transmissions from M915 heavy equipment transporters. CMC Nurnberg also has a TARP end item mission for the M35A2 2½-ton truck. Its corps-level missions include tank gun fire simulators and some training devices. A second category of IMMA staffed by foreign nationals is the Equipment Support Activity (ESA). The three ESAs in Europe are located at Kaiserslautern and Mannheim in the 21st SUPCOM and at Vilseck in the 7thATC. The DS/GS missions of the Kaiserslautern and Mannheim ESAs are identical: they support automotive, construction, and communications-electronics equipment. ESA Vilseck has DS/GS missions for automotive, combat vehicles, and weapons/armament. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

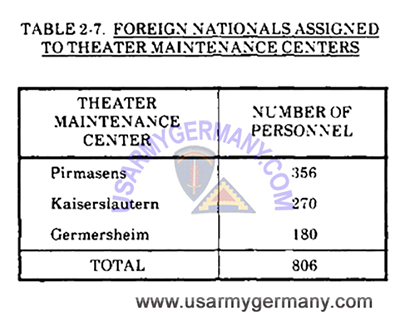

| Table 2-6 shows the foreign national staffing at the ESAs. The ESA at Kaiserslautern is the largest, nearly twice the size of the one at Mannheim. ESA Vilseck is the smallest. As in the CMCs, the ESAs have very few military personnel assigned: a total of nine for all three activities. ESA Mannheim has ten DACs, while the other two have none. Both of the ESAs in the 21st SUPCOM support the FY85 TARP, with Mannheim having 100,278 financed man-hours and Kaiserslautern having 69,802 man-hours. The last category of IMMA with a significant military equipment DS/GS role is the Theater Maintenance Center (TMC). The three such centers in Europe are Germersheim Maintenance Center (GMC), Kaiserslautern Maintenance Center (KMC), and Pirmasens Communications-Electronics Maintenance Center (PCMC). (3) The missions of these centers vary significantly. While both GMC and KMC have automotive and combat vehicle missions, KMC also has a mission for construction equipment. Neither supports communications-electronics equipment or weapons/armament. On the other hand, PCMC is almost exclusively devoted to electronics and communications work although that mission often entails some sheet metal, structural, and electromechanical tasks for shelter refurbishment jobs. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

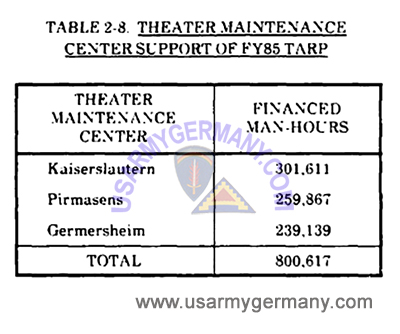

| Foreign national staffing for the theater maintenance centers is shown in Table 2-7. PCMC is the largest center; GMC is the smallest. The data in Table 2-7 do not include the 12 military and 2 DAC personnel assigned to PCMC nor the 5 military and 7 DAC personnel assigned to KMC. GMC has neither military nor DAC personnel. Also excluded from the totals in Table 2-7 are foreign national personnel in a CSU attached to the PCMC; those personnel are discussed in the next section. The theater maintenance centers are distinguished from the CMCs, and ESAs in three important ways. First, they do not generally support individual units directly but rather support the supply system by performing GS-level repairs. Second, they are geographically and organizationally located behind the corps. Third, much of the work of the theater maintenance centers is dedicated to support of the TARP. TARP support by the theater maintenance centers represents a significant contribution to the accomplishment of that program. The extent of that support is indicated by the financed manhours provided by each center to the FY85 TARP. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| As shown in Table 2-8, the total financed manhours for all three centers is 800,617 with Kaiserslautern being the largest contributor with 301,611 man-hours and the other two close behind. To add some perspective to the theater maintenance centers' contributions to the TARP, the man-hours they provide represent approximately 20 percent of the FY85 TARP workload. Foreign nationals are the primary source of staffing at the IMMAs. At activities other than IMMAs, however, foreign national individual hires are used only to augment the maintenance capability of the activity. The most notable of these activities is the 70th Transportation Battalion. The 70th Transportation Battalion, located in Mannheim, is an Aviation Intermediate Maintenance (AVIM) unit assigned to the 21st SUPCOM. Its maintenance mission includes direct AVIM and backup unit maintenance support for 23 units, direct AVIM support for all theater CH-47 and fixed-wing aircraft, and backup AVIM support to corps AVIM battalions. The 70th also has other aviation logistics missions, and missions for air transport and airfield operations. Of its 604 personnel (excluding U.S. Forces Dependent Hires), 413 are military and 191 are foreign nationals. For its AVIM mission, the 70th has 98 military personnel and 161 foreign nationals, a total AVIM staffing of 259. The 70th Transportation Battalion also receives contract support to augment its maintenance capability for the CH-47. That support is discussed in a subsequent section. Another example of the use of foreign nationals to augment maintenance organizations is the 517th Maintenance Battalion, with headquarters in Zweibrücken. The primary mission of the 517th is to provide calibration and maintenance support for general-purpose test, measurement, and diagnostic equipment (TMDE) and some special-purpose TMDE. It also has a nucleonics laboratory that provides radiac instrument calibration and repair and it operates a radioactive material disposal facility for the U.S. European Command. To accomplish these missions, the 517th Maintenance Battalion is organized into a headquarters element and three operating companies. Battalion staffing totals 470 military personnel assigned with an augmentation of 63 civilians (9 DACs and 54 foreign nationals). For the most part, the DACs are used in supervisory positions, while the foreign nationals are used in support roles. (4) Exceptions are found in the maintenance company located in Pirmasens. That company (in addition to providing the same TMDE calibration and repair support as the other two companies) has two unique missions for which it employs foreign nationals: to operate the nucleonics laboratory and to assist PCMC in support of its special repair authority for selected items. Part of the staffing for both missions consists of 21 foreign nationals, 8 for the laboratory and 13 for the special repair authority. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Footnotes: (1) For the purpose of this study, the term "host nation support" includes all maintenance support involving some type of commitment or endorsement by governmental or quasi-governmental agencies of foreign governments. (2) Throughout the balance of this section, only locations in countries other than the FRG will be specifically identified. (3) A fourth theater maintenance center, the Luxembourg Maintenance Center (LMC), is often considered an organic activity. It is, however, actually a form of host nation support and its role is discussed in a subsequent section. (4) The 517th Maintenance Battalion is also augmented by CSU, host nation support, and contractor personnel. That augmentation is discussed separately in subsequent sections of this " chapter. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Labor Service Units providing Ordnance Maintenace in USAREUR | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1985 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (Source: The Role of Civilians in Maintaining Military Equipment, Vol. II, Joseph R. Wilk, Eugene A. Narragon & Brian E. Mansir, Logistics Management Institute, December 1985) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Civilian Support Unit Another form of civilian staffing used by the Army in the direct maintenance mission is the CSU. Those units are quasi-military in that they are organized and operate, in many respects, like military units. They have unit missions, a rank structure, uniforms, unit billeting and messing facilities, and orderly and administrative tasks in addition to their primary jobs. Also, CSU hiring procedures and pay scales are different from those for individual direct-hire foreign nationals. However, CSUs cannot be assigned military missions nor be deployed. The 103 CSUs in Europe have a total assigned strength of nearly 12,000 personnel, and have a variety of missions including security, ordnance, engineer, supply, transportation, medical service and supply, signal support, and maintenance. Maintenance CSUs are organized into battalion level units called Civilian Support Centers (CSCs) and company level units called Civilian Support Groups (CSGs). The latter are typically staffed at about 60 percent of equivalent-mission, full strength U.S. military companies. Some maintenance CSUs have mixed missions. That is, part of a unit may be devoted to direct maintenance while another part may be assigned to related functions such as Care of Supplies in Storage (COSIS). When these mixed missions occur, the COSIS mission is generally consistent with the unit's primary mission. For example, if a unit's primary mission is DS maintenance of' automotive equipment, then its COSIS mission is likely to be centered around the upkeep of wheeled vehicles in storage. COSIS missions frequently require some CSUs to station detachments away from the unit's primary location. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

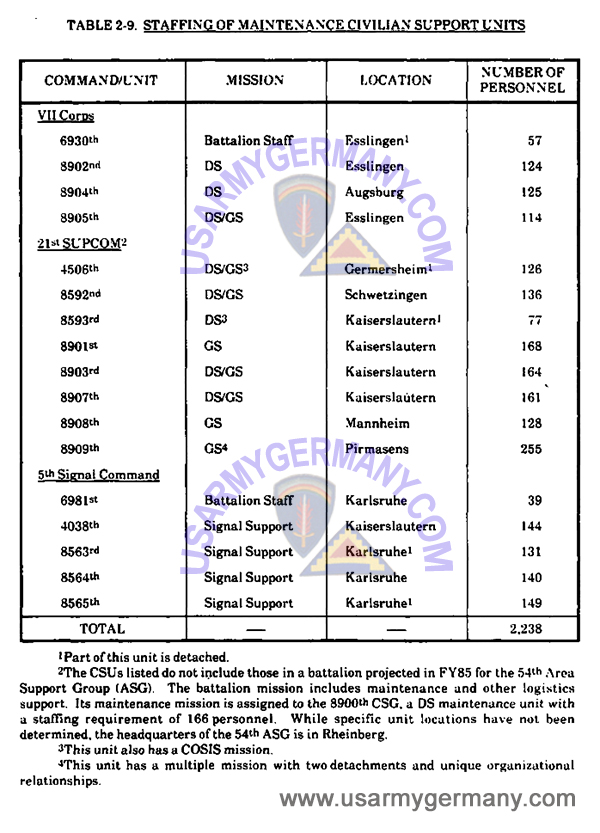

| Table 2-9 shows the current staffing, missions, locations, and command assignments of maintenance CSUs. (1) The staffing data include all assigned personnel even though some may be performing related tasks or assigned to detached locations. The location shown in the table is that of unit headquarters where most personnel are usually assigned. The staffing of maintenance CSUs totals 2,238 personnel, with slightly more than one-half in units assigned to the 21st SUPCOM. The other maintenance CSUs are either in VII Corps or the 5th Signal Command. The V Corps has no maintenance CSUs although other types of CSUs are assigned. CSUs have a variety of maintenance missions. Many support operating units directly, some are assigned TARP or COSIS missions, and others, such as units in the 5th Signal Command, have diverse missions. CSUs in VII Corps generally support operating units, while those in the 21st SUPCOM serve in several roles. For example, the 4506th and 8593rd both support automotive equipment, with the 4506th also supporting light tracked vehicles. Both have COSIS missions, though not to the same degree. As much as 85 percent of the 8593rd's capacity is devoted to COSIS workload, versus just a small fraction of the 4506th's. Both also have detachments located at equipment storage sites. Approximately one-third of the personnel of the 8593rd is detached to the North Point site in Moersfeld. The 4506th has a smaller detachment at Berg, the South Point site. The 8592nd supports bridging equipment, operates the USAREUR bridge park, and performs some TARP repairs. The 8901st operates much like a heavy equipment maintenance company, providing support to automotive, armament, and fire control equipment. So, too, does the 8903rd, but with special emphasis on fire control equipment. Both units, along with the 8908th, are assigned TARP missions. The 8907th does automotive work and supports the TARP, being the primary contributor to the Jeep body replacement program. It also operates a battery shop for KMC. The 8909th differs from other units, both in its diverse missions and unusual organizational relationships. As a unit, it reports directly to General Support Center Germersheim but assigns most of its personnel to PCMC in support of the TARP communications-electronics mission. The 8909th also provides 26 personnel to the 517th Maintenance Battalion, a unit of AMC-Europe. Those personnel serve in three different roles. Eight personnel are used in supply and support functions at battalion headquarters in ZweibrUcken, 18 are in Pirmasens assisting the 524th Maintenance Company; of the 18, 10 are employed in the nucleonics laboratory and the remaining 8 support the special repair authorization mission for TMDE. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Only CSGs in the 21st SUPCOM support the TARP. The extent of that support is shown in Table 2-10. Together, the five CSGs provide 350,826 man-hours to the TARP, which represents approximately 9 percent of the total TARP workload, with the preponderance contributed by the 8907th. Not shown in the table is the TARP contribution of the 8909th. That unit provides substantial communications-electronics support to the TARP by the contribution of its personnel assigned to PCMC. Data for that support are commingled with PCMC's TARP production data, however, and are not separately available. The maintenance mission of the CSUs assigned to the 5th Signal Command cannot be readily separated from their other signal support functions. Typically, those units lay cables, repair antenna towers, operate and maintain microwave sites, and test and repair cables. For example, the 8563rd in Karlsruhe has 131 assigned personnel, of which 54 lay, test, and repair cables: 16 maintain antennas in the Kaiserslautern area; and 61 operate and maintain 21 microwave sites. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Footnote: (1) CSUs also are assigned to the U S. Army Combat Equipment Group, Europe, to maintain equipment in storage. Those CSUs are described in a subsequent section of this report. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Class V Ordnance Service in USAREUR | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (Source: DA Pam 700-16, The Army Ammunition Management System, Dec 1982) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Standard Army Ammunition System (SAAS) Prior to 1973, the Army did not have a standard automated ammunition management system for use in the field. Operations were basically manual; however, several commands had unique ADP systems for providing class V management information and developing the WARS (Worldwide Ammunition Resporting System) report for ARRCOM (US Army Armament Materiel Readiness Command). In 1972, a detailed analysis of current ongoing automated systems was undertaken to determine a system that would serve as the theater system baseline. The system selected was the US Army Pacific (USARPAC) Central Munitions System. In addition, WARS was selected as the baseline reporting system between the major command (Level 1) and the national level. In June 1973, the converted USARPAC Central Munitions System was tested by the 60th Ordnance Group, USAREUR. This system was accepted by USAREUR in July 1973, renamed SAAS (Standard Army Ammunition System), and designated as the level 1 (theater) system. Theater Application - Level 1. The Theater Materiel Management Center (in USAREUR, the 200th TAMMC performs theater ammunition management) is an activity which performs centralized theater inventory management, maintains visibility of all theater assets, and acts as the theater's interface with the DARCOM wholesale level. It performs the mission and functions of supply management, maintenance, serviceability, transportation, intransit control, and SAAS/NICP interface management. It also provides the required logistical/tactical interface management. Ammunition assets are divided into five general categories: Below Theater Application - Level 3. The stock control activity (Level 3) is an activity which exercises stock control over the assets of one or more storage activities. Storage Activity - Level 4. The storage activity (Level 4) is one whose principal mission is to exercise custody of stocks for distribution to the user (Direct Support Unit role) or to other storage activities (General Support Unit role). This is an operational level and operates in a manual environment. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (1) PWRMS are part of the theater's war reserve and represent stockage levels of mission-essential items to support post D-day combat consumption until resupply from CONUS facilities can be accomplished. (2) The basic load is that quantity of non-nuclear ammunition the theater commander authorizes for wartime purposes and requires to be designated for and carried into combat by a unit. The basic load provides the unit sufficient ammunition to sustain itself in combat until the unit can be resupplied. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Standard USAREUR Munitions Systems (SUMS) To accommodate the installation of the SAAS Level 1 system in USAREUR, the Miesau Army Depot lot locator system was renamed as the SUMS and expanded to provide a reporting capability to SAAS level 1. SUMS operates in two modes, the "depot mode" and the "visbility mode." The "depot mode" accommodates those processes necessary for managing and controlling the day-to-day operations of an accountable supply distribution activity (ASDA) such as Miesau Army Depot. (Class V accountability in USAREUR is decentralized.) This service is provided also for the 84th Ordnance Battalion in support of its management of approximately thirty (30) prestock points stocking war reserves and units' basic loads. SUMS serves all other USAREUR munitions activities in the non-accountable "visibility mode." |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| As of 31 December 1981, USAREUR had 838,000 short tons of storage capacity on the continent and in the United Kingdom. The largest of the sites were as follows: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (1) The 122,000 short ton capacity of the "Other" category is spread among 30-plus sites whose individual capacities range from medium to very small. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (Source: GAO Report, NSIAD-94-148R Military Ammunition in Europe, 1994) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ORDNANCE AMMUNITION COMPANIES, mid-1980s | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (1) The 4230th CSG (Guard), with six detachments, provides physical security for all Class V storage sites under 15th Ord Bn control (1984). | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| The corps ordnance ammunition battalion operates a number of prestock points (PSP's) throughout the corps area of responsibility. These PSP's contain every kind of conventional ammunition required by the combat units that they support. Each PSP is divided into sections which store the same type of ammo. The ammo is stored in protected concrete bunkers and each supported unit has its own designated location for the ammo storage unique to its mission. Ammo stocks at the PSP's can be mobilized at any time and transported to Corps forward combat positions. The concept of "modeling" used in USAREUR means that each unit's basic load - all the ammo needed for the initial stages of a conflict - is stored at the same location. In the event of an outbreak of hostilities, the units would move to their PSP's, upload their ammo and transport it to the field. The Ordnance Ammunition Company is composed (1985) of A Forward Storage Theater Site (FSTS) consists of approx. 20 bunkers or storage magazines A Prestock Point (PSP) consists of approx. 30 magazines |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (Source: German Bundesarchiv, via Rick Anders, and other sources) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (Sources: Base Realignment and Closure announcements, early 1990s, HQ USAREUR) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Ordnance - Special Weapons Support | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (Source: Building for Peace: US Army Engineers in Europe, 1945-1991) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (Source: Tactical Nuclear Weapons Responsibility: Ordnance Versus Field Artillery, by Lt Col Joseph A. Fields, ORD, 8 March 1990) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| In a Study Project (US Army War College) paper written by Lt Col Fields in 1990, the author examines the role of the Ordnance Corps and Field Artillery in providing supply support for theater nuclear weapons for US-firing units versus non-US firing units and discusses some recommendations for improving the current (late 1980s) system of theater nuclear weapons support. Our focus will be on the parts of the eport that describe the current structure and functions of tactical nuclear weapons support. (If you want to read the entire report, you can find a PDF version on the DTIC.mil website.) LTC Fields' research in the matter included - besides his own personal experience within the Ordnance Corps where he was involved directly with the supply of conventional and nuclear ammunition in Europe as well as Korea - numerous interviews with senior ORD and FA officers as well as a visit to the 59th Ordnance Brigade in Germany. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| MISSION DEFINITION There are several elements of tactical nuclear weapon's support that differentiate it from that of standard conventional ammunition. These peculiarities and their second order requirements form the basis of the functions to be discussed. The principles of control, accountability, security, field storage, maintenance, and safety are the salient factors. These factors thus lead to the mission to be discussed and the missions being performed by both field artillery as well as ordnance units. The primary mission that I will examine is that of custody. A unit that is designated a custodial unit is one "charged with responsibility to maintain custody of nuclear weapons, issue nuclear weapons to delivery units, and conduct nuclear logistical operations." The sub-elements that are derived from this custodial mission are numerous. Contained within the "issue" element are such diverse sub-parts as the transportation of the weapon, documenting the appropriate transfer of possession, and ancillary tasks such as appointment of custodial agents. It is evident that safety and security weigh heavily during all elements of the "issue" process as with all other processes. Finally, the definition of "conduct nuclear logistical operations," contains tasks such as performing:

While this list is not all inclusive, it serves to highlight the vast majority of tasks performed at the "custodial unit" level. CURRENT STRUCTURE FOR MISSION ACCOMPLISHMENT The doctrine for the nuclear weapon support operation is in consonance with the currently deployed structure. Within a theater of operation (USAREUR, for example), there exists an ordnance brigade which commands the requisite number of ordnance battalions which provide supply support to the U.S. deployed corps. The recently published FPM 9-6 (1 Sept 89) discusses the inclusion of Field Artillery in the supply support mission by stating: Within a theater of operations that is a combined theater, USAAGs (U.S. Army Artillery Groups) are assigned to support host nation forces. During peacetime, these USAAGs are composed of a US ordnance company and US field artillery detachments (USFADs) and are responsible for storing and maintaining nuclear warheads and nuclear projectiles in support of host nation forces. Host nation security forces provide external security for nuclear weapons stored by USAAG ordnance companies and USFADs. There is one other organization, which exists in the Eighth United States Army, that is similar to the artillery groups. It is the Weapons Support Detachment-Korea (WSD-K). Its' unclassified mission statement is to be prepared to "provide Nuclear Support Teams (NET) prepared to deliver nuclear weapons using Republic of Korea weapons systems under the provisions of the Eighth United States Army Tactical Nuclear Standing Operating Procedures." This unit, with an average military strength of 163, is so unique in its tactical nuclear weapons mission and "one-of-a-kind" command relationships that I will not include it In further discussion. Suffice it to say that it exists and it is different from the custodial unit definition previously listed. If a re-look of the organization of WSD-K Ss deemed necessary, it should be undertaken as a separate study. There are approximately 170 officers and 1335 enlisted soldiers with artillery occupational specialties serving in the command and control and custodial unit operating structures of the NATO artillery groups. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Related Links: |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The PzArtBtl was a direct support artillery unit attached to the German armored and mechanized infantry brigade.

The PzArtBtl was a direct support artillery unit attached to the German armored and mechanized infantry brigade.

LRSP Sites in Germany 1981

LRSP Sites in Germany 1981